Call Us:(410) 676-1600

Copyright 2012: ASP Machine | Machine Shop Maryland | All rights reserved.

708 Pulaski Hwy. Ste.B

Welding and Other Services in Baltimore

Services

At our professional Baltimore machine shop, we offer a wide array of quality services. We offer milling turning, polishing, reverse engineering, scanning, drawings and welding in Baltimore. For a quick description of these services, see the descriptions below.

- Milling

A milling machine is a machine tool used to machine solid materials. Milling machines are often classed in two basic forms, horizontal and vertical, which refers to the orientation of the main spindle. Milling machines can perform a vast number of operations, from simple (e.g., slot and keyway cutting, planning, drilling) to complex (e.g., contouring, diesinking). Cutting fluid is often pumped to the cutting site to cool and lubricate the cut and to wash away the resulting swarf.

- Turning

A metal lathe or metalworking lathe is a large class of lathes designed for precisely machining relatively hard materials. They were originally designed to machine metals; however, with the advent of plastics and other materials, and with their inherent versatility, they are used in a wide range of applications, and a broad range of materials. These rigid machine tools remove material from a rotating workpiece via the (typically linear) movements of various cutting tools, such as tool bits and drill bits.

- Welding

Welding is a fabrication or sculptural process that joins materials, usually metals or thermoplastics, by causing coalescence. This is often done by melting the workpieces and adding a filler material to form a pool of molten material (the weld pool) that cools to become a strong joint, with pressure sometimes used in conjunction with heat, or by itself, to produce the weld.

- Polishing

Polishing and buffing are finishing processes for smoothing a workpiece's surface using an abrasive and a work wheel. Technically polishing refers to processes that use an abrasive that is glued to the work wheel, while buffing uses a loose abrasive applied to the work wheel. Polishing is a more aggressive process while buffing is less harsh, which leads to a smoother, brighter finish. A common misconception is that a polished surface has a mirror bright finish, however most mirror bright finishes are actually buffed.

- Reverse Engineering

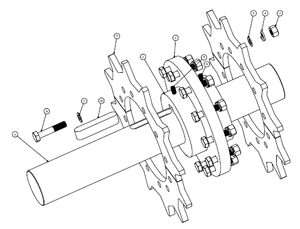

Reverse engineering is the process of discovering the technological principles of a device, object, or system through analysis of its structure, function, and operation. It often involves taking something (e.g., a mechanical device, electronic component, software program) apart and analyzing its workings in detail to be used in maintenance, or to try to make a new device or program that does the same thing without using or simply duplicating (without understanding) the original.

- Scanning

As computer-aided design (CAD) has become more popular, reverse engineering has become a viable method to create a 3D virtual model of an existing physical part for use in 3D CAD, CAM, CAE or other software. The reverse-engineering process involves measuring an object and then reconstructing it as a 3D model. The physical object can be measured using 3D scanning technologies like CMMs, laser scanners, structured light digitizers, or Industrial CT Scanning (computed tomography). The measured data alone, usually represented as a point cloud, lacks topological information and is therefore often processed and modeled into a more usable format such as a triangular-faced mesh, a set of NURBS surfaces, or a CAD model.

- Drawings

A working drawing is a type of technical drawing, which is part of the documentation needed to build an engineering product. In engineering, these drawings show all necessary data to manufacture a given object, such as dimensions and angles.

For more detailed information about our services, contact one of our professionals at our machine shop in Maryland.